When embarking on a building or woodworking project, one critical decision revolves around the type of plywood to utilize. Two of the most recognized grades are F14 and F17 plywood. Understanding the differences, applications, and strengths of each can significantly influence the success of your project. This article delves into the nuances of F14 and F17 plywood, providing insight on which may suit your needs best.

Understanding Plywood Grades

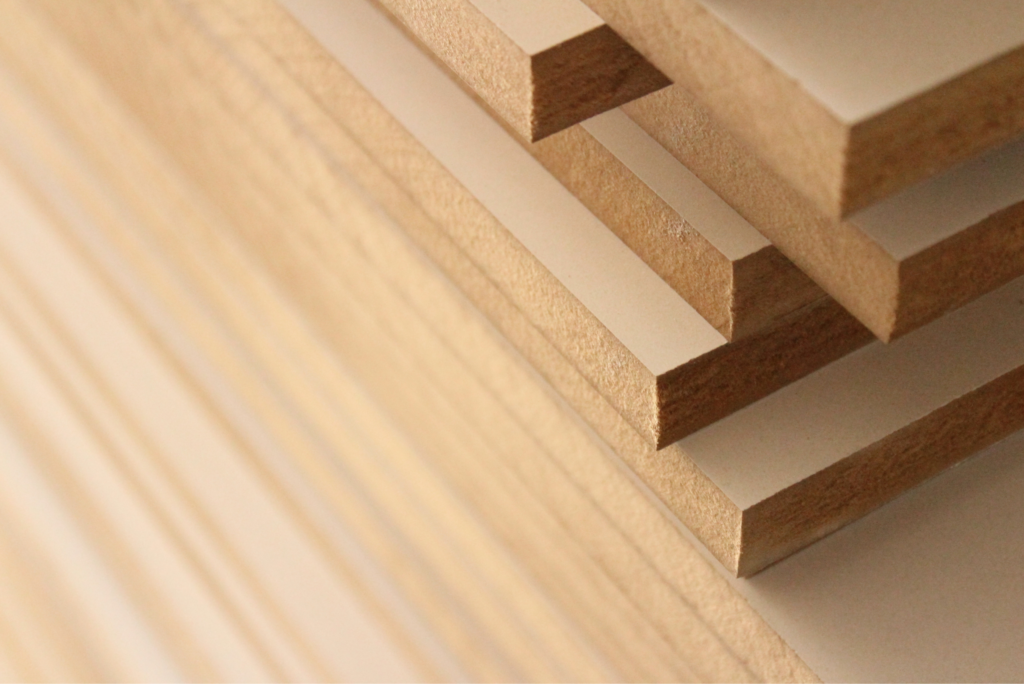

Plywood grading is essential for determining the suitability of a sheet for specific applications. It is a reflection of its quality, appearance, soundness, and structural integrity, offering valuable guidance for builders and woodworkers.

Furthermore, F14 plywood is endorsed by relevant building codes and standards, making it a reliable choice for most structural applications. Its versatility also means that it can be used in both residential and commercial projects, ranging from simple cabinetry to more complex structural frameworks.

The Basics of Plywood Grading

Plywood is classified based on various factors including the type of wood used, the manufacturing process, and specific performance characteristics. Grades generally range from A to D, where A denotes a high-quality surface and D represents the lowest grade, often featuring knots and defects. However, the F14 and F17 grading standards are often used in structural applications where performance is paramount.

An understanding of these grades will not only help you select the right plywood but also ensure safety and longevity in your projects. When choosing plywood, always consider the end use and environmental conditions which it must endure. For instance, marine-grade plywood is specifically designed to withstand moisture and is treated to resist rot, making it ideal for boat building and other applications exposed to water.

F14 Plywood: An Overview

F14 plywood is recognized for its high strength-to-weight ratio and durability. It is commonly employed in applications requiring strength and rigidity, such as flooring, roofing, and wall sheathing. Made from high-quality timber, F14 plywood holds an excellent reputation among builders and architects.

This grade typically includes a combination of hardwood and softwood veneers, providing it with structural stability and a fine finish. Projects that demand resilience, particularly in harsh weather conditions, often benefit from using F14 plywood due to its resistance to boiling water and significant moisture. Additionally, F14 plywood is often treated with adhesives that enhance its durability and resistance to delamination, ensuring that it maintains its integrity over time, even in challenging environments.

F17 Plywood: An Overview

On the other hand, F17 plywood is engineered for superior performance in more demanding environments. It is often used in applications such as load-bearing structures, heavy-duty flooring, and high-stress installations. Characterized by an even higher strength rating than F14, F17 plywood encompasses quality timber and advanced manufacturing processes that ensure optimal performance.

The critical feature of F17 plywood is its ability to withstand substantial loads over extended periods. It usually involves more stringent testing standards, confirming its reliability in heavy-duty applications. Because of its robust design, F17 plywood is commonly utilized in commercial construction, scaffolding, and high-performance engineering projects. Its enhanced durability also makes it suitable for use in industrial settings where heavy machinery may be present, ensuring that it can handle the rigors of a demanding work environment.

Moreover, F17 plywood is often used in applications where fire resistance is a concern, as certain treatments can be applied to improve its fire-retardant properties. This makes it a popular choice for projects that require compliance with stringent safety regulations, further solidifying its place as a top-tier material in the plywood grading hierarchy.

Key Differences Between F14 and F17 Plywood

While both F14 and F17 plywood serve important roles in construction and woodworking, some critical differences can influence your selection process based on project requirements.

Material Composition

The composition of these plywood types significantly contributes to their performance. F14 plywood often includes mixed hardwood and softwood veneers, which provide a balanced combination of aesthetic appeal and mechanical performance. This grade is suitable for projects where appearance and strength are equally prioritized, allowing for visible applications where finishing is essential. The variety of woods used can also affect the final look, with options ranging from rich, warm tones to lighter, more neutral shades, catering to diverse design preferences.

In contrast, F17 plywood typically employs more homogeneous materials designed to withstand extreme conditions. The engineered composition makes it inherently stronger and more resilient, making it ideal for scenarios where structural integrity takes precedence over aesthetics. This plywood is often treated to resist moisture and pests, enhancing its longevity in outdoor applications or environments prone to wear and tear. Such characteristics make F17 a preferred choice for heavy-duty construction projects, including flooring and roofing, where reliability is crucial.

Strength and Durability

In terms of strength, F17 plywood holds a notable advantage. Its engineering accounts for higher load-bearing capacities, making it preferable for industrial and commercial applications. For projects dealing with substantial weight or where long-term use is expected, F17 plywood is the go-to option due to its superior durability and lower risk of failure. Additionally, F17’s resistance to warping and splitting under stress further solidifies its reputation as a dependable choice in demanding environments.

F14 plywood, while still strong, is typically reserved for projects that do not require the extensive load-bearing capacity of F17. It is highly durable for residential applications and on-demand, providing satisfactory performance without the advanced specifications that F17 boasts. This makes F14 an excellent option for furniture, cabinetry, and interior paneling, where the emphasis is on visual appeal and moderate strength rather than extreme durability. Moreover, F14’s versatility allows it to be easily cut and shaped, making it a favorite among hobbyists and craftsmen. Learn more about versatility at https://edu-versity.in/

Cost Considerations

Cost is another critical factor to consider when selecting between F14 and F17 plywood. Generally, F14 plywood is more budget-friendly, appealing to casual builders or DIY enthusiasts looking for a quality material without the hefty price tag. Its cost-effectiveness makes it a popular choice for non-structural projects or applications with lighter load requirements. Many homeowners find F14 to be an ideal solution for renovations and smaller-scale construction, where the focus is on affordability without sacrificing quality.

Conversely, F17 plywood’s heightened engineering capabilities and material quality often result in a higher price point. However, this investment can be justified through longevity, strength, and overall performance, particularly in projects that warrant a more robust material. For contractors and builders, choosing F17 can translate into savings over time, as its durability reduces the need for frequent replacements or repairs. This long-term perspective is essential for commercial projects, where the cost of materials must align with the expected lifespan and performance requirements of the structure.

Choosing the Right Plywood for Your Project

With a clear understanding of F14 and F17 plywood, the next step is evaluating your specific project needs. This section tackles how to assess your requirements and make the most informed choice.

Assessing Your Project Needs

The first step in selecting the right plywood is to analyze the scope of your project. Questions to consider include:

- What is the primary purpose of the plywood?

- Will the plywood be exposed to moisture, heat, or other harsh conditions?

- Is aesthetic appearance a major concern for your project?

- What load-bearing capacities does your project require?

Answering these questions will guide you toward selecting the appropriate grade for your needs. For heavy-duty applications, F17 is advisable, while F14 might suffice for lighter, aesthetically driven projects. Additionally, consider the dimensions and thickness of the plywood sheets, as these factors can influence both the structural integrity and the overall look of your finished product. For example, thicker sheets may provide better sound insulation and durability, which could be essential for certain applications like flooring or cabinetry.

Environmental Factors to Consider

Environmental factors can have a significant impact on the type of plywood chosen. Consider the climatic conditions, humidity levels, and potential exposure to chemicals or weight loads. Understanding these variables can help determine whether to opt for the more robust F17 or the versatile F14. Furthermore, if your project is intended for outdoor use, it is vital to select plywood that is treated for weather resistance, as untreated plywood can warp, swell, or delaminate when exposed to the elements.

Also, establishing if your project adheres to any specific building regulations or environmental standards could affect your decision. Compliance with codes often necessitates higher-grade plywood, particularly in commercial construction. In addition, exploring eco-friendly options, such as plywood sourced from sustainably managed forests, can not only meet regulatory requirements but also contribute positively to environmental conservation efforts.

Safety and Compliance Standards

Safety should never be overlooked in any construction project. Both F14 and F17 plywood meet established safety standards and regulations; however, confirming compliance with local guidelines is crucial before making a final selection. Look into factors like fire resistance, structural stability, and long-term performance under different conditions. It’s also beneficial to research the manufacturer’s reputation and the quality assurance processes they have in place, as this can provide additional peace of mind regarding the safety and reliability of the plywood you choose.

Always prioritize selecting plywood that surpasses regulatory expectations, ensuring both quality and safety in your projects. Additionally, consider the potential for future renovations or modifications; selecting a higher-grade plywood may offer more versatility and longevity, allowing for easier adjustments down the line. By taking a comprehensive approach to your selection process, you can ensure that your project not only meets immediate needs but also stands the test of time. To find more about modifications click here.

Working with F14 and F17 Plywood

Once you’ve made your selection, the next step is to understand how to work effectively with either F14 or F17 plywood. Each has its unique tools and techniques to ensure optimal results.

Tools and Techniques for F14 Plywood

When working with F14 plywood, typical woodworking tools like circular saws, jigsaws, and table saws can be used effectively. Due to its relatively straightforward nature, F14 can be worked with traditional woodworking skills, allowing for easy cutting, shaping, and finishing.

Techniques such as using pre-drilled holes for screws can prevent the plywood from splitting, ensuring a cleaner finish. Moreover, it is advisable to sand edges and surfaces to achieve a polished look, which is especially important in visible applications.

Tools and Techniques for F17 Plywood

F17 plywood requires slightly more advanced handling due to its strength and density. Tools must be sharp and of high quality to ensure precise cuts. A table saw with a fine-tooth blade often provides the best results, as rough cutting can lead to splintering or chipping of the edges.

When joining F17 plywood, using heavy-duty clamps and adequately spaced fasteners is critical. The specific needs of your project will dictate the best techniques, but incorporating modern tools can lead to superior finishes.

In conclusion, choosing between F14 and F17 plywood fundamentally depends on your project’s specific requirements, including strength, aesthetic needs, budget, and environmental conditions. By understanding the characteristics and applications of each type, you can ensure a successful outcome in your woodworking or construction endeavors.

Find more about f17 grade plywood on: F17 Grade Plywood Why It’s the Preferred Choice for Formwork